Brochures and Videos

News & Press-Releases

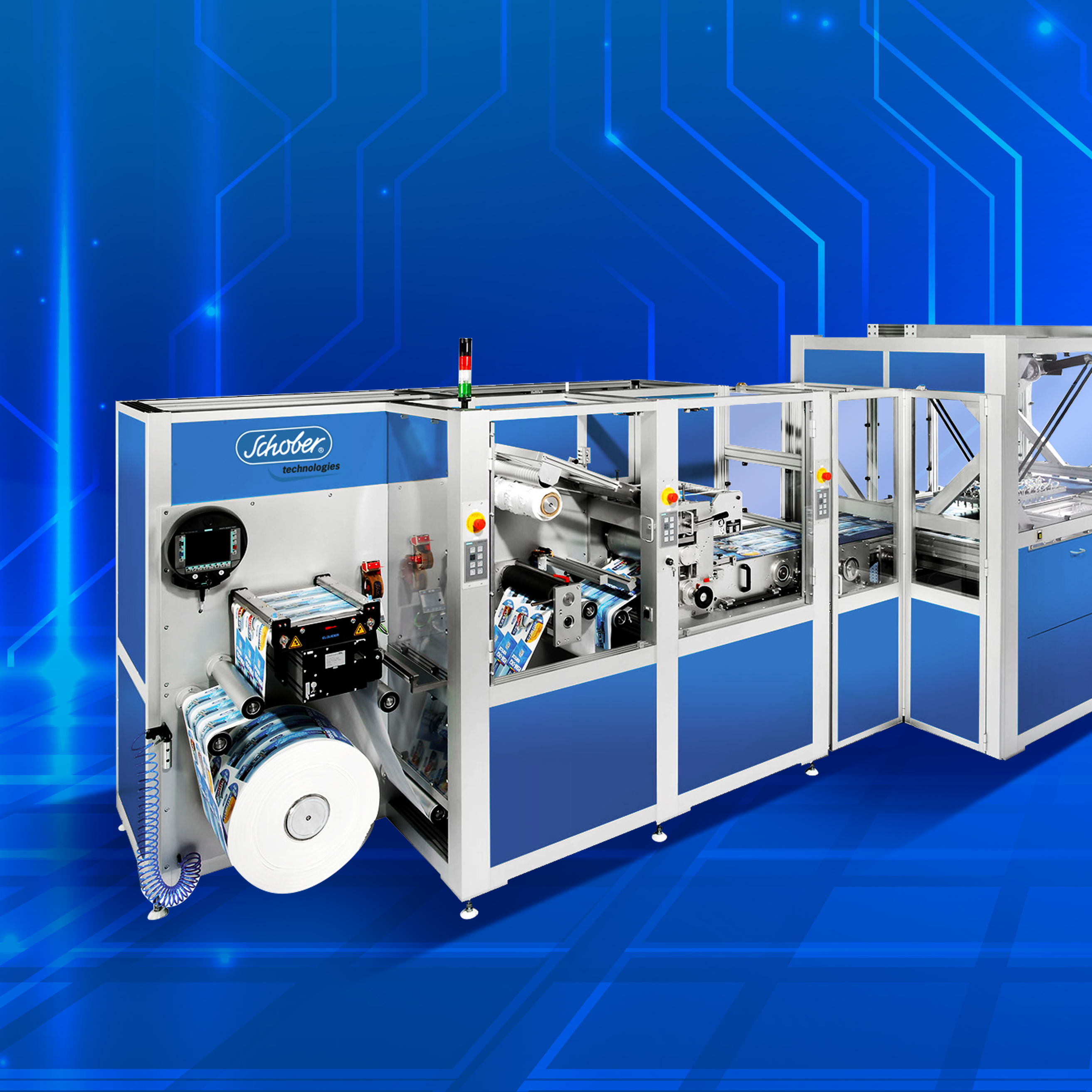

RSM410 IML/MX with Twin Spider - Punching and stacking with maximum efficiency

Schobertechnologies GmbH is one of the leading specialists in the development, design and manufacture of high-quality rotary cutting and punching machines. From development to production, assembly, commissioning and worldwide after-sales service, our focus is always on the perfect workflow for our customers. This is the only way to ensure innovative high-performance solutions and the efficient processing of technical products.

With our RSM series, we not only offer you a variety of options to realize your projects, but also to make your work steps more future-oriented.

The current rotary cutting and punching machines are equipped with the latest SINAMICS drives and control systems. These use an efficient energy management process, which, thanks to the coordinated elements of the drive train, leads to a gain in energy efficiency of up to 10%.

The RSM410 IML/MX with Twin Spider setup, which has been successfully installed several times, is unparalleled in this respect.

The Twin Spider is specially designed for high-speed cutting and stacking of in-mold labels. This innovative high-performance solution combines acceleration, speed and precision at a continuous web speed.

The innovative drive technology of the RSM410 IML/MX combines continuous and vector rotary cutting technology in an in-setting process, always in register with the print. In this way, a large number of print format lengths can be covered with one tool scope.

With the Twin Spider set-up, the RSM410 IML/MX offers a programmable, robot-controlled high-speed stacking and counting system ("spider"). The robot-controlled delivery developed for this purpose makes it possible to stack different products with the same print image.

Thanks to its special features, the RSM410 IML/MX with Twin Spider is the answer to increasing market requirements and future challenges in digital printing.

Schobertechnologies also offers you innovative high-performance solutions in a small format. The integrated rotary processing systems for creasing, embossing, cutting, punching, transferring and sealing can be offered with additional base frames, drives or complete processing sections, depending on the conditions on site, and can be individually adapted to your requirements.

The Schobertechnologies punching modules are an example for this innovative technology. In particular, these are suitable for the production of profile and special punching.

Every Schober machine is designed in such a way that it can also be upgraded in the future to ensure a maximum life cycle.

Would you like to experience technology highlights from Schobertechnologies live?

Schobertechnologies presents innovative products, solutions and technologies at all relevant trade fairs worldwide. We look forward to welcoming you personally at a trade fair and presenting our innovations to you.

Visit us and experience our exhibition highlights live.

High efficient cutting and stacking of inmould labels at LABEL SUMMIT LATIN AMERICA 2024

Schobertechnologies is pleased to announce its participation at Label Summit Latin America 2024. Our Team is looking forward to welcoming you at our booth. If you have specific projects, we will be happy to advise you. You are more than welcome to bring along samples, photos, drawings, … If you do not have any specific projects for the moment, we will still be happy to show you our exhibits. We are sure that you will be able to draw ideas for the future.

Brochures

Videos

RSM IML/MX-DIGI-VARICUT

RSM IML/MX Twin Spider

RSM HD-DIGI-VARICUT

FLSM Rotary punching machine