and perforating

of inmold labels

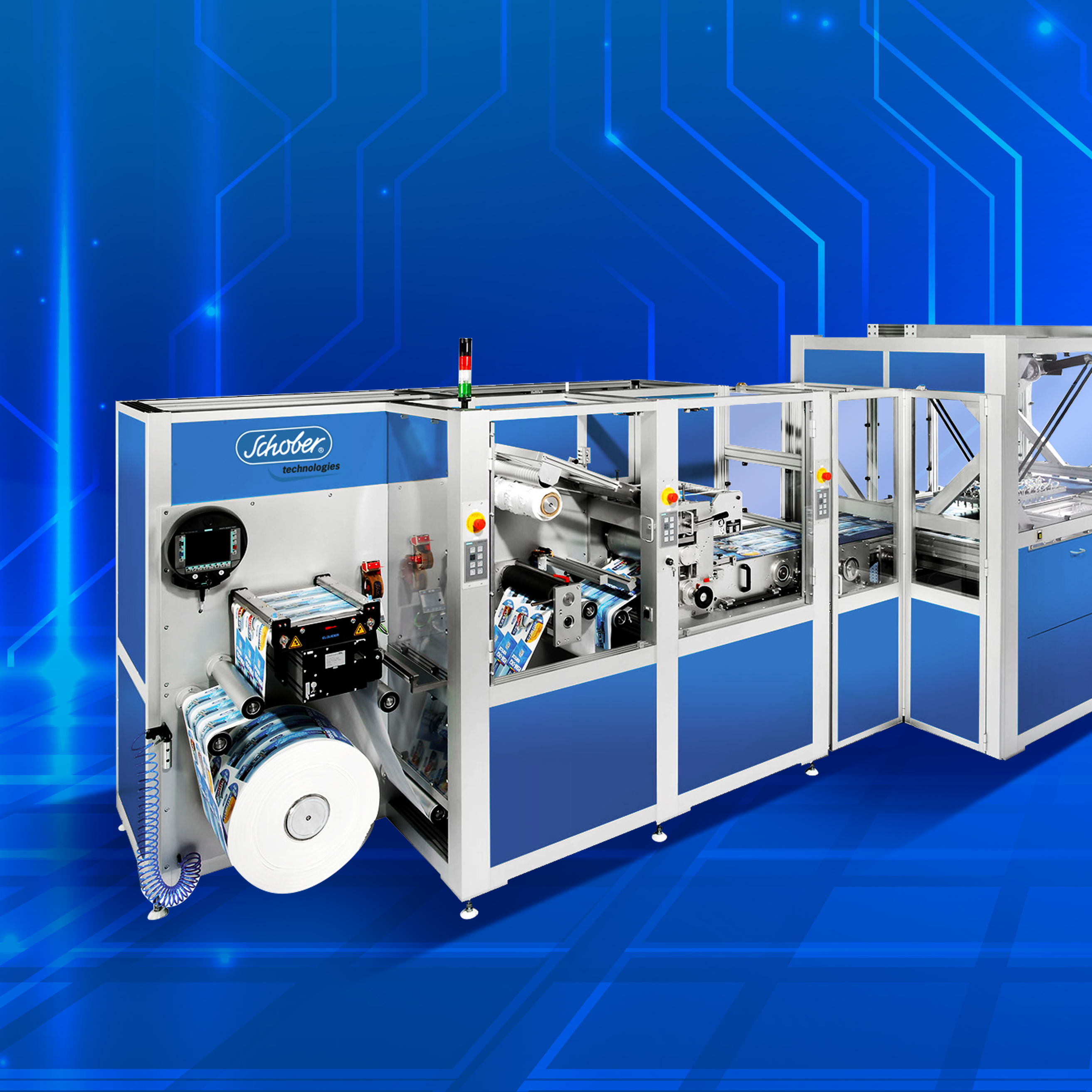

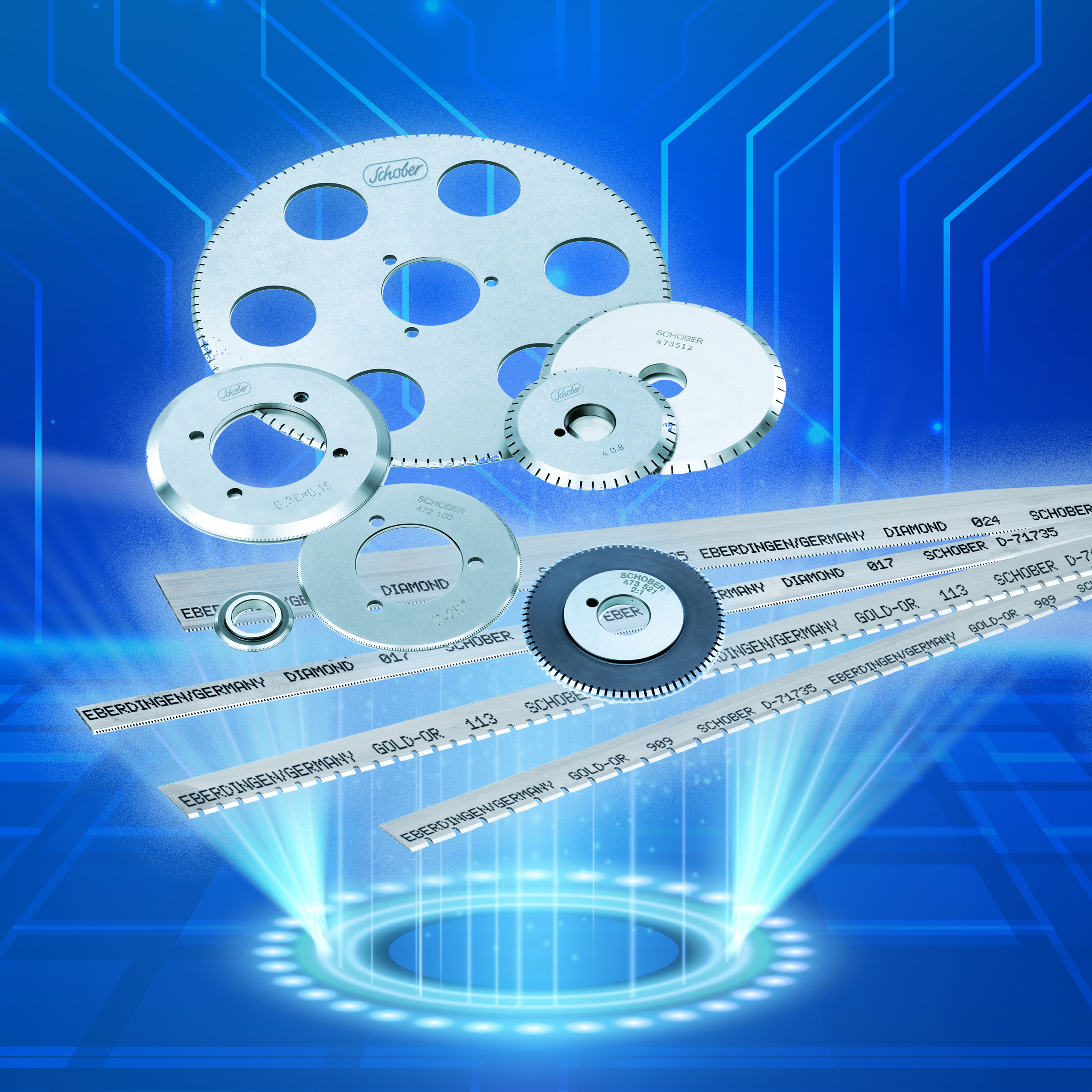

Schobertechnologies develops, manufactures and supplies rotary tools, modules or complete production lines in a wide variety of designs. Mechanical cutting or perforating can be done by using cutting-, anvil cylinders, circular knives and industrial blades.

The combination of cutting materials can be specially adapted to your application. Production speeds of up to 600 m/min are common for rotary cutting.

The different cutting processes are used in the production of aseptic packaging, blister packaging, batteries & fuel cells, folding cartons, beverage carriers, cigarette packaging, tissue-, tea- & coffee packaging, test strips, sanitary towels, diapers, incontinence products, pads, solar cells, ...

thanks to micrometric adjustment and precise monitoring of the cutting/processing gap. Exact product separation, a long lifetime of the cutting plates and targeted wear compensation speak for themselves.

with two independent processing stations. Both are equipped with magnetic cylinders and can be fitted with specific cutting- and creasing plates depending on the product characteristics.

for creasing, embossing, cutting, punching, transferring and sealing. Depending on the conditions on site, additional base frames, drives or complete processing sections can be offered, individually adapted to your requirements.

available in our web shop (24/7)

You can buy all the necessary parts for highly efficient cutting and perforating.

We also offer a professional and sustainable resharpening service of your tools.

The TECHNOVATION WORLD is a web based application in which innovative finishing technologies can be experienced interactively and in 3D. Detached from time and space, you can enter the world anytime and anywhere and start a new digital adventure.