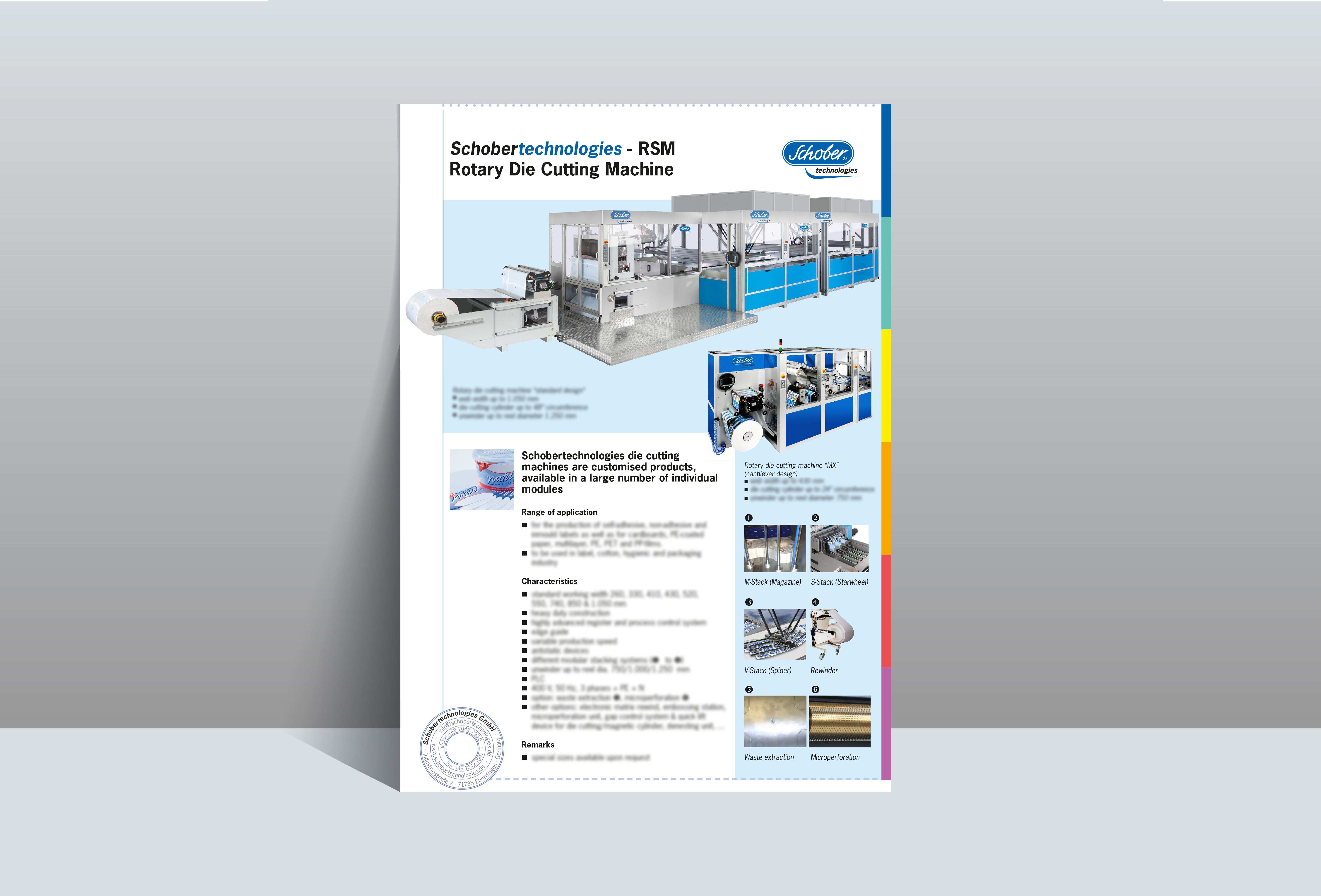

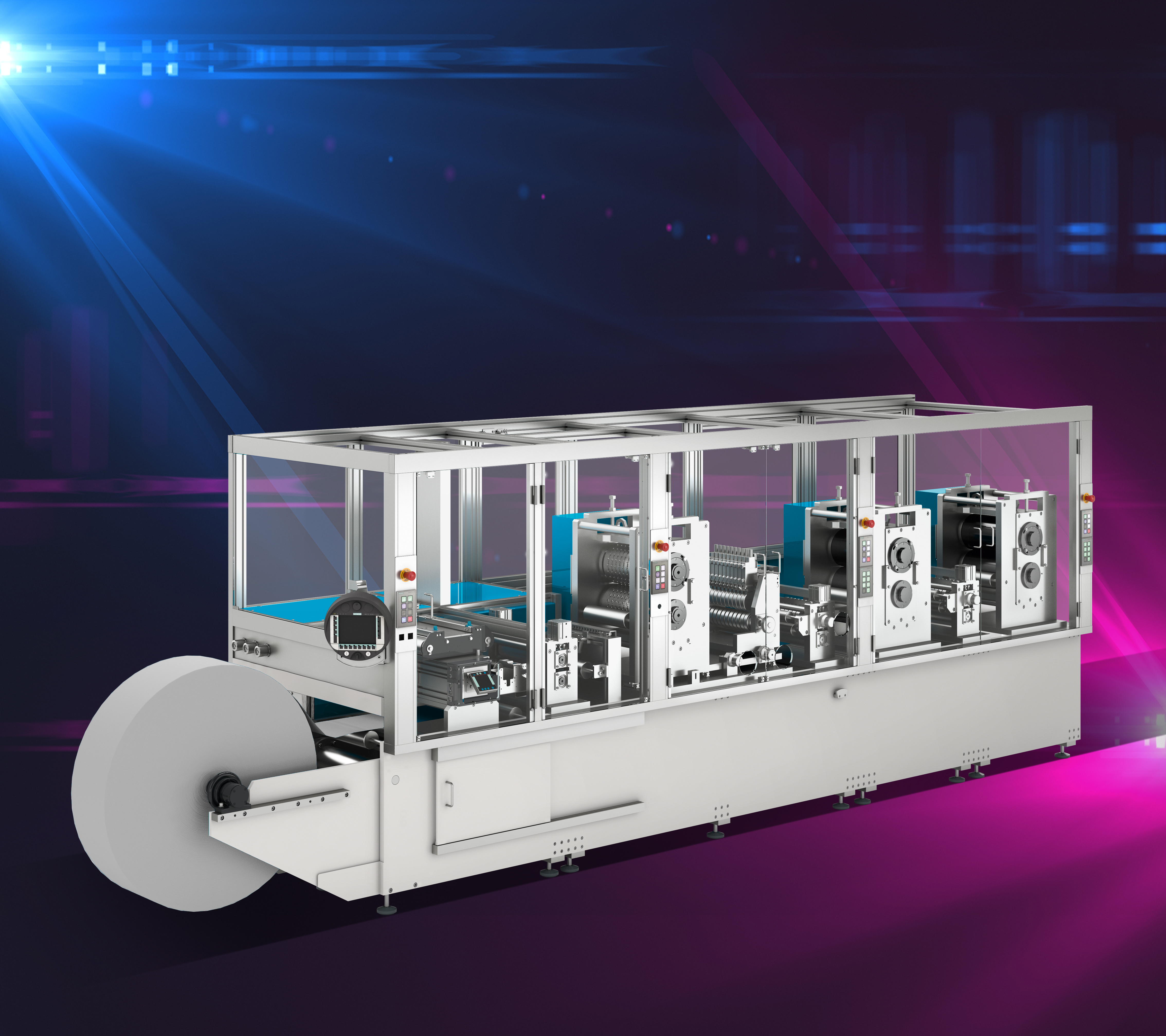

Proven rotary cutting technology

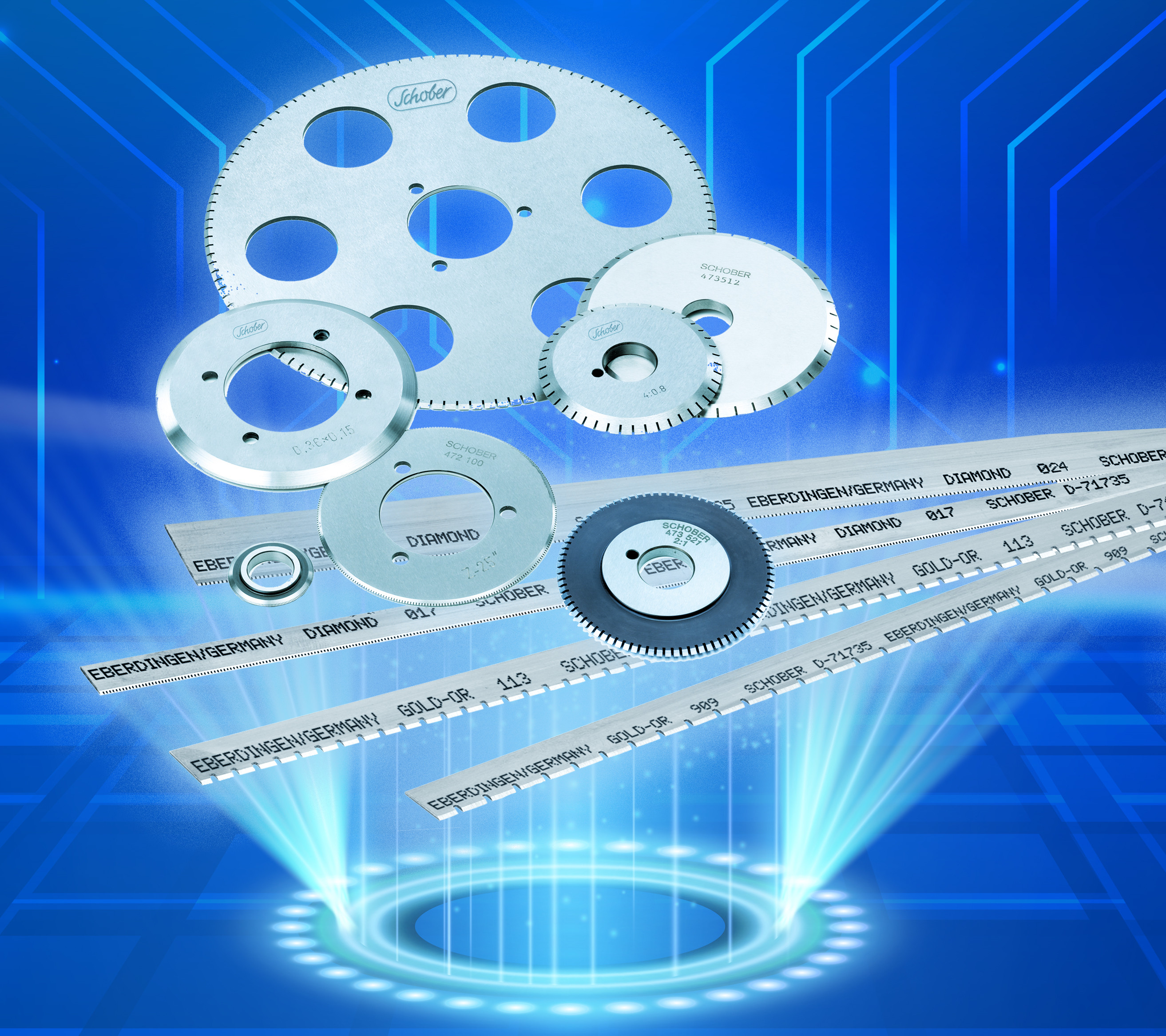

The modern rotary cutting machine is characterized by the use of a proven rotary cutting technology. The use of high-precision and long-life magnetic cylinders can guarantee an optimal and safe holding force of the cutting plate.

The magnetic cylinders, built into high-performance cutting units, are equipped with:

- Preset pressure settings

- High-precision bearings and bearing blocks

- Gap Control System for accurate wear compensation of the cutting edge

- Centrally located quick lift from the magnetic cylinder to the impression cylinder (without loss of register)