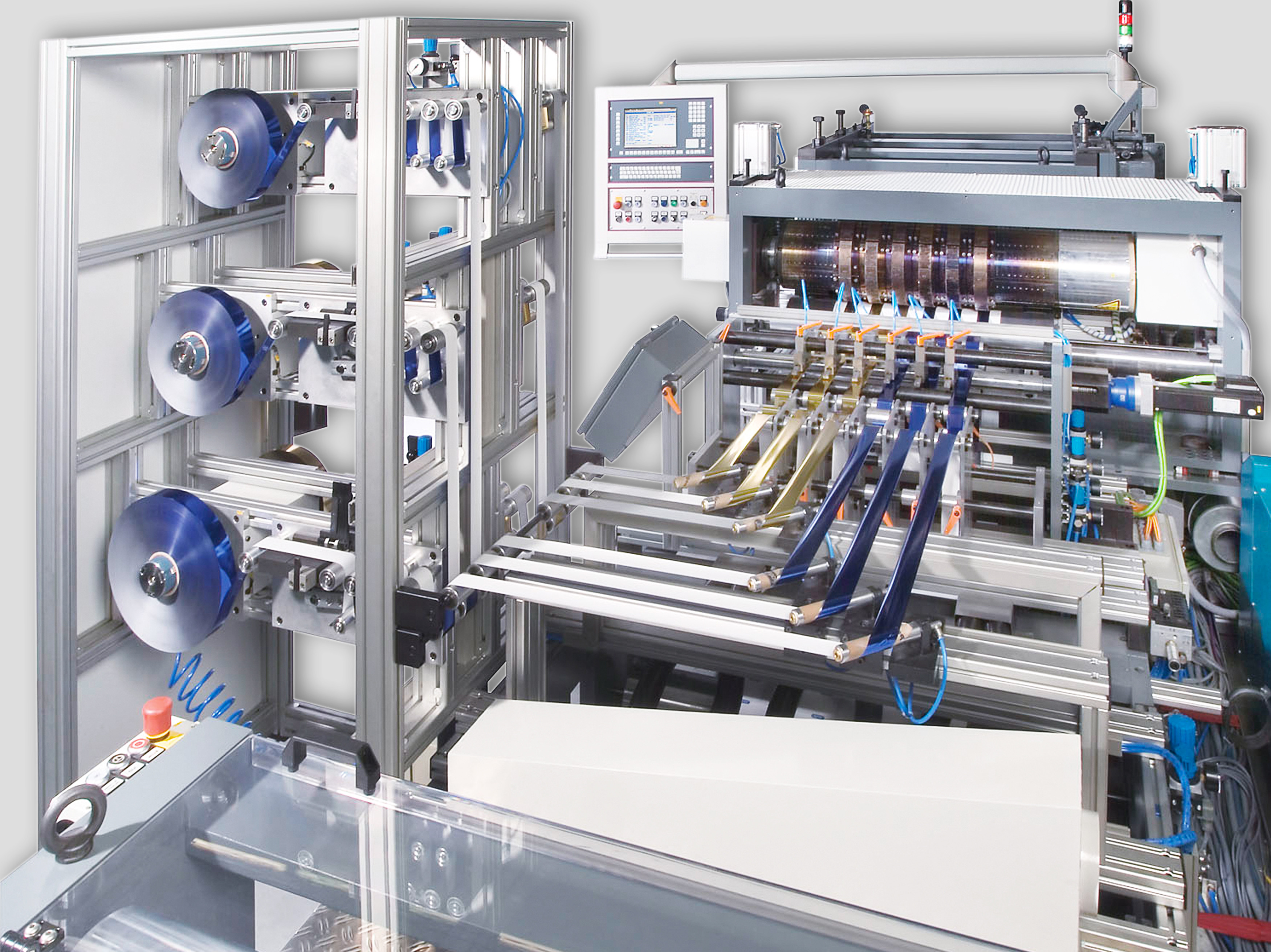

Rotary finishing of packaging and folding cartons

Schobertechnologies expertise gives you a decisive productivity advantage in the processing of films, cardboard and laminates. By choosing Schobertechnologies, you get the perfect technology for processing the materials for manufacturing packaging right from the start. We have the right solutions for all work steps, such as cutting, punching, creasing or embossing, for filling liquids, packaging food and other products.

Everything is possible: tear-open perforations, viewing windows, openings, hot stamping foils, application of holograms and the production of packaging with barrier properties. Materials such as PE, cardboard and aluminium layers, both individually and in combination, are processed with maximum security.

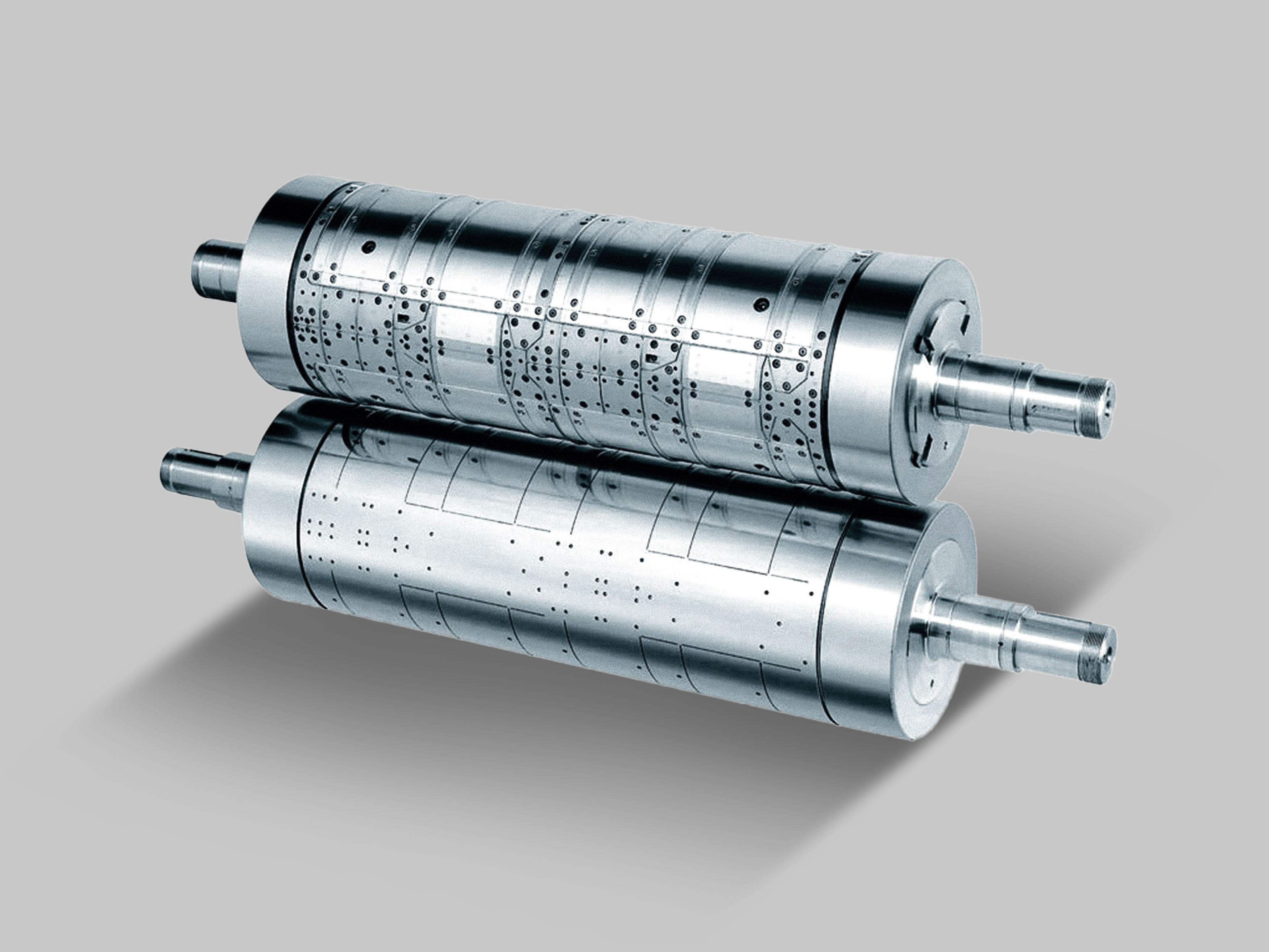

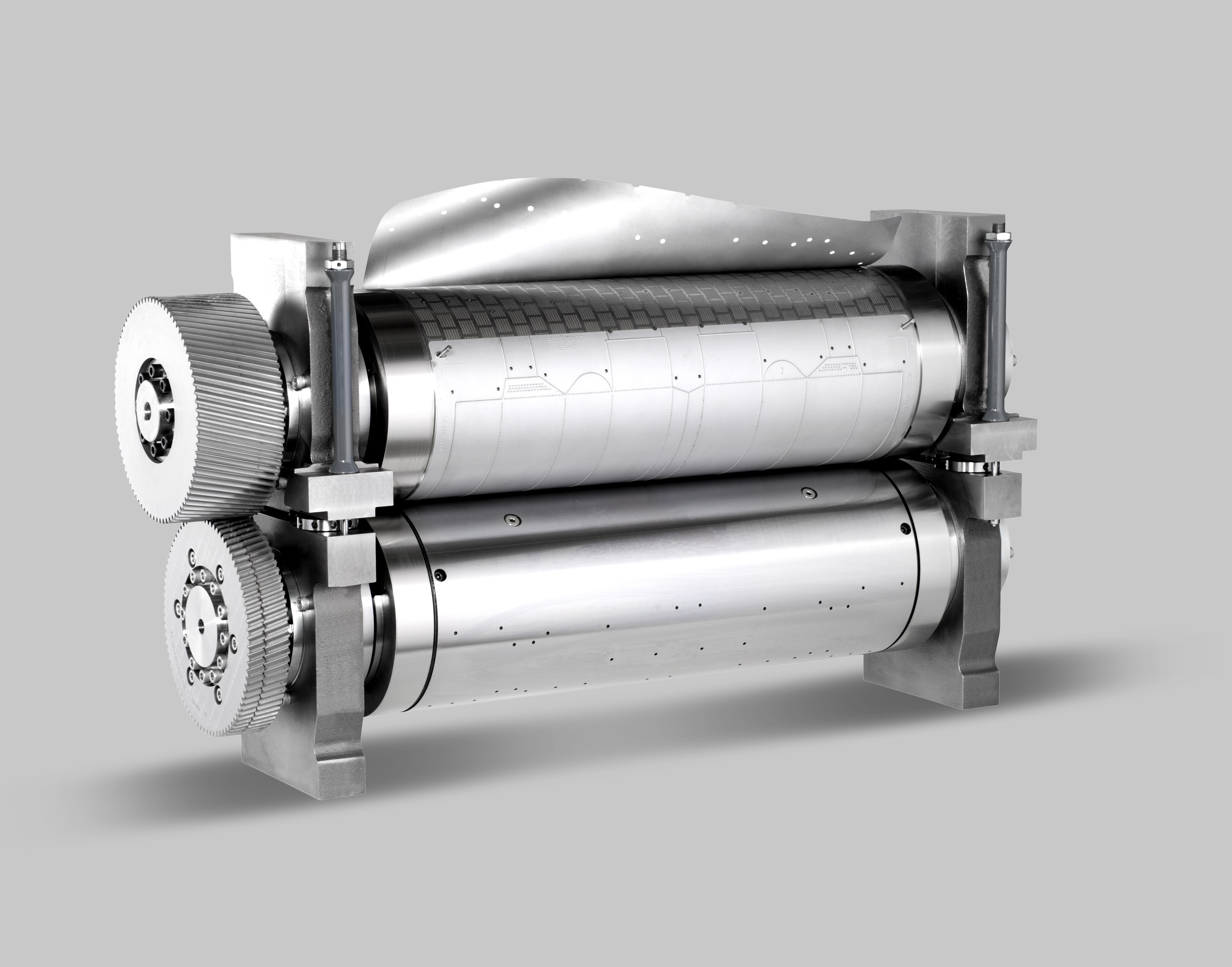

Rotary production of blister packaging

Cutting cylinder for holding moulded products, such as blister packaging for toothbrushes. The cutting edge height can be several millimetres and enables additional resharpening cycles as long as the product dimensions permit.

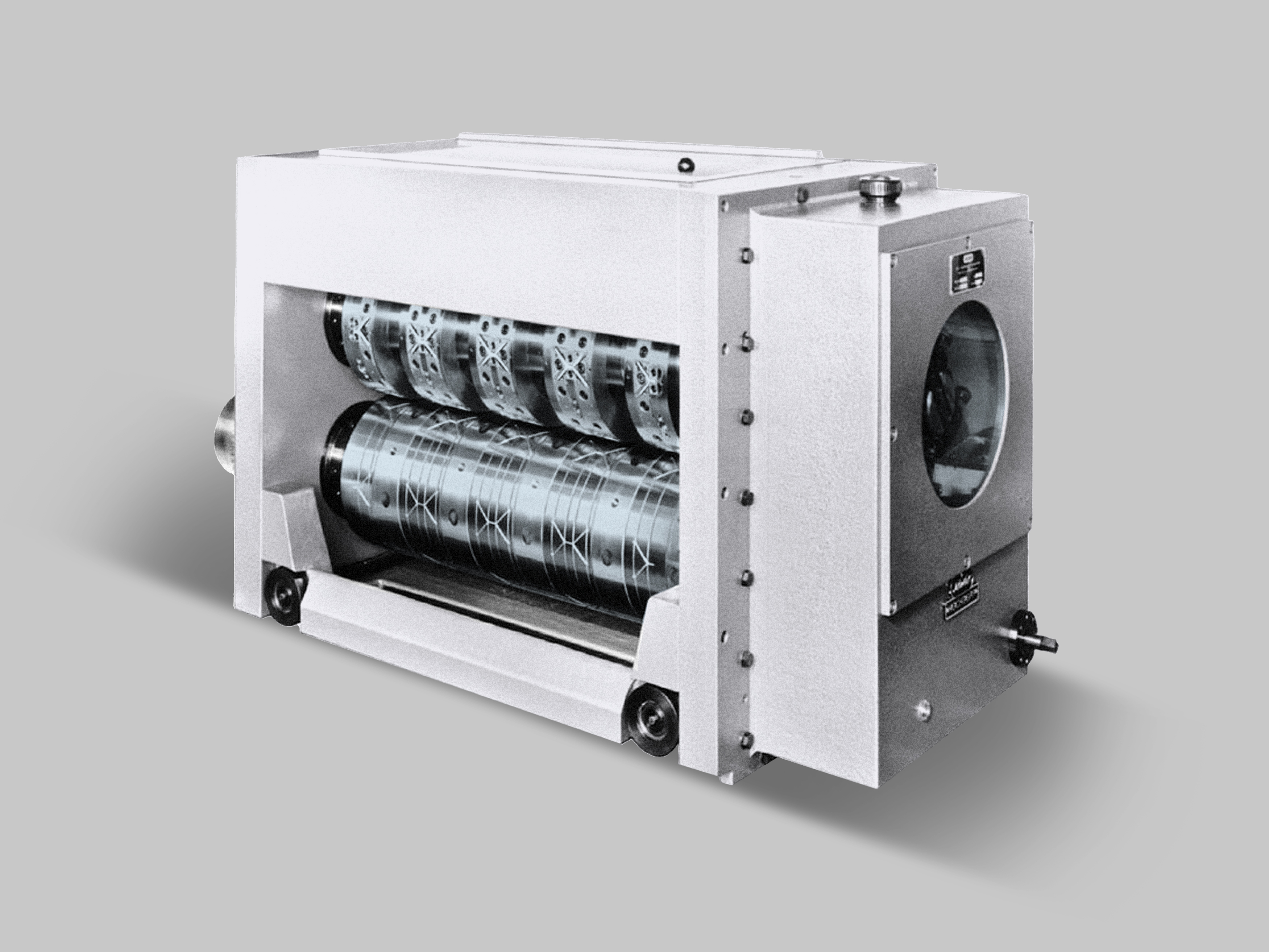

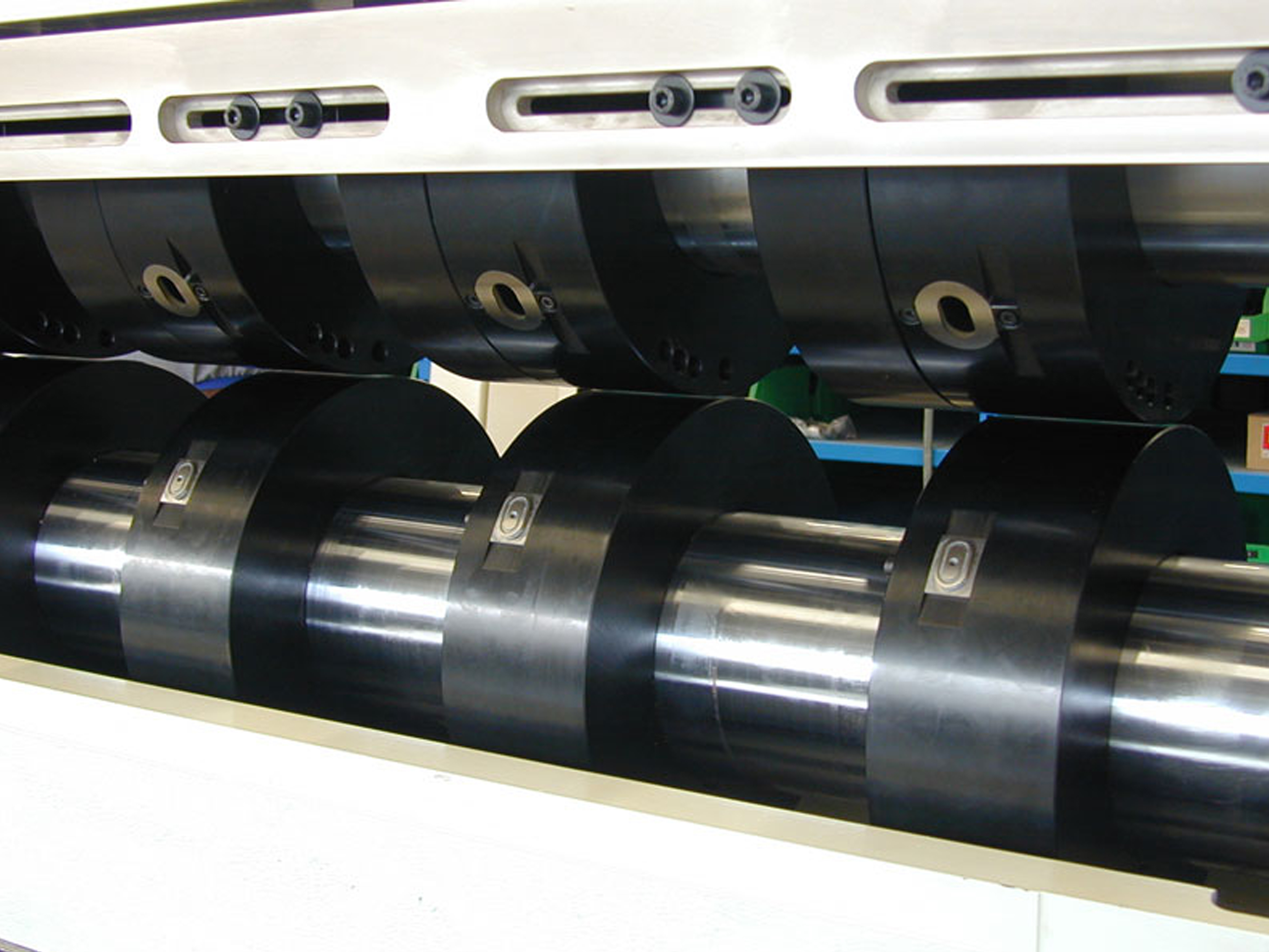

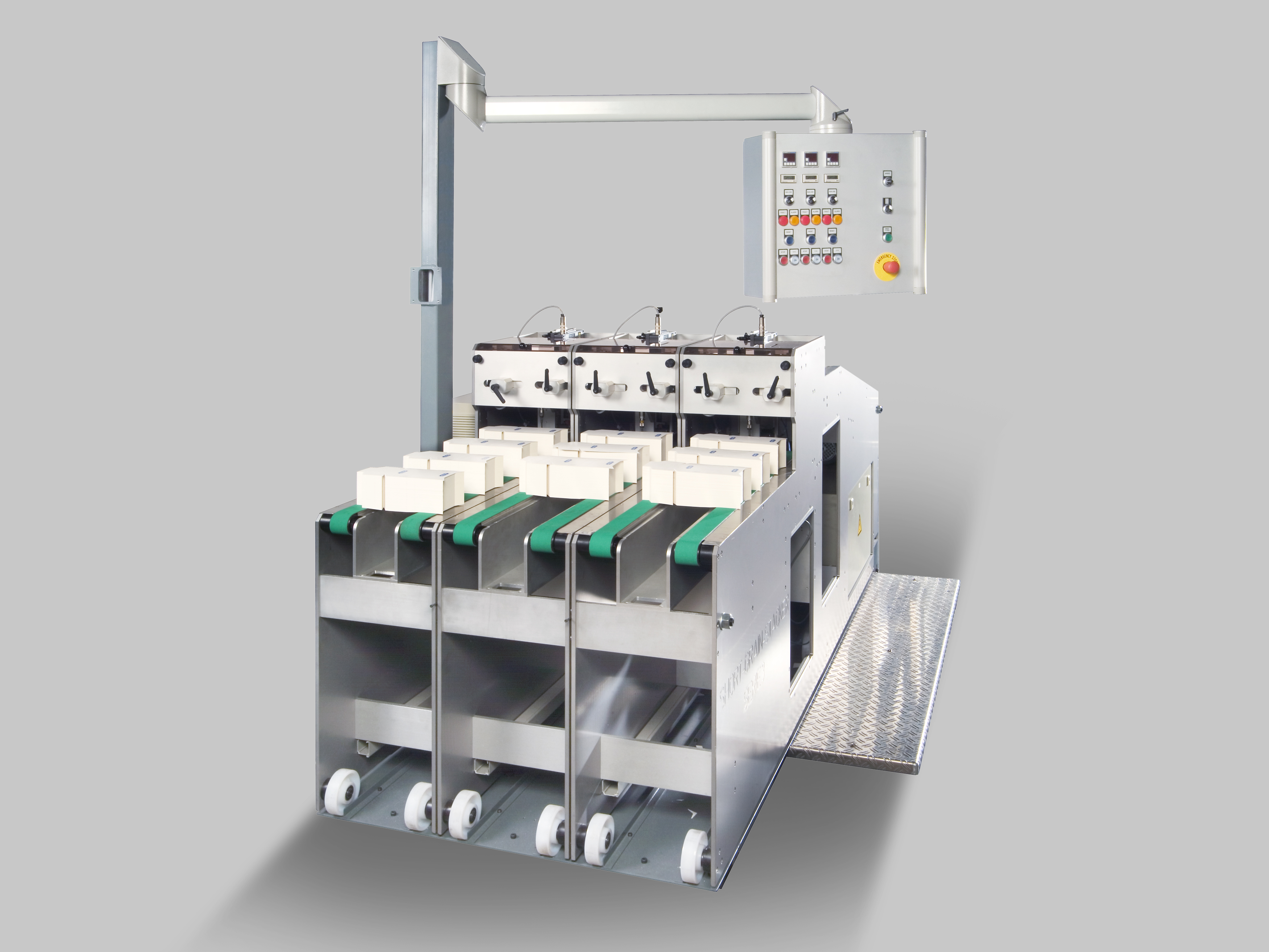

Efficient cutting and creasing of folding cartons

with 2 independent processing stations. These are equipped with magnetic cylinders and can be fitted with specific cutting and creasing plates depending on the product dimensions.

All information at one glance

Read all about innovative cutting, die-cutting, creasing and embossing in our brochure "Rotary finishing of packaging, inmould labels and folding cartons"